TP3 – Anodes for Methane Oxidation

Methane is one of the molecules being most difficult to activate, since essentially any primary oxidation product of methane is easier to oxidize than methane itself, and thus is further oxidized, typically to CO2. , The only method viable on technical scale for methane conversion to valuable products is first steam reforming to synthesis gas, followed by conversion of the synthesis gas to methanol or hydrocarbons. However, this is a process which suffers from tremendous economies of scale, especially for the syngas production, and thus, over the years many highly interesting alternative approaches have been explored, which use innovative chemistry for the activation of methane without leading to full oxidation.

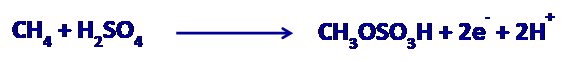

One highly interesting approach is the one reported by Periana, building upon earlier work by Shilov. Methane is oxidized to methylbisulfate in concentrated sulfuric acid – or preferably in oleum – over an h2-(2,2′-bipyrimidyl)dichloroplatinum(II) catalyst, and the resulting methylbisulfate can by hydrolyzed to methanol. However, one of the key problems is the separation of the methylbisulfate from the reaction medium. This problem could potentially be solved by an anode reaction:

This reaction would not lead to water and SO2 formation, so that reoxidation of the SO2 would be obsolete and the detrimental dilution of the oleum could be avoided. During the project it shall be explored whether such an electrosynthetic reaction is viable, what kinds of catalysts are optimal, and how the reaction would proceed.

If the direct electrooxidation turns out to be impossible, for whatever reason, a second best option could be the electrocatalytic re-oxidation of the SO2, which is formed in the normal Periana reaction.

UNODE- DFG Forschergruppe 2982

UNODE- DFG Forschergruppe 2982